How AI Significantly Improves Simulation Infrastructures in Healthcare

Innovative technologies have applied their potential to product design and development over the past few decades, achieving amazing results. According to the study shown in https://www.has-sante.fr/jcms/c_2626164/fr/evaluation-des-infrastructures-de-simulation-en-sante, some companies have been active in healthcare simulation with the goal of improving the medical industry.

Innovative technologies have applied their potential to product design and development over the past few decades, achieving amazing results. According to the study shown in https://www.has-sante.fr/jcms/c_2626164/fr/evaluation-des-infrastructures-de-simulation-en-sante, some companies have been active in healthcare simulation with the goal of improving the medical industry.

With cloud computing getting a lot of help, AI is becoming more accessible in terms of meeting the various needs in healthcare. It walks through the user’s implicit flow and decides on customer activities, saving you from building multiple iterations of the test. In manufacturing companies, AI can save hundreds of costs that could be wasted in product development and testing.

Reduce Human Error

To have the capacity to withstand technological versions, companies will now get huge benefits from integrating artificial intelligence into their medical operations like actions, marketing, funds, health or merchandise expansion, etc. It automates all human work to eliminate the possibility of error. Scientists have found that in the future, AI will perform all the intellectual actions performed by a human to a considerable extent. So far, AI has already performed some tasks correctly. And that’s probably why technology is accused of taking jobs away from humans.

Reduce Operational Costs

As a lifesaver, AI takes over any dangerous and complicated tasks in industries. It effectively reduces operational costs. The cost of skilled and qualified labor required to design and develop a software product is significantly higher than that of automated machines. Moreover, lower operating costs help companies develop more innovative products at very affordable prices. A bigger product means more profits, and AI can be incredibly helpful in this regard. More importantly, it eliminates tedious, boring, and repetitive tasks when it comes to all the complexities.

Ensure Quality

Let’s do some research in product engineering companies, there is always a great need for quality assurance analysts. When it comes to product management, it’s imperative to be sure that a product meets quality standards, as evidenced by the fact that product testing only takes up 40-50% of the function before a product is sent to production. Let’s look at another element of this coin. If a QA engineer gets much more involved in product testing and takes up more time, product development could be derailed.

Develop Medical Devices

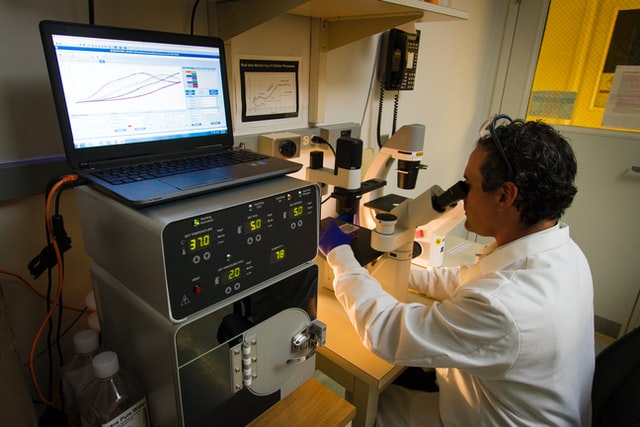

Incorporating AI can allow medical to automate the analysis of these things and be efficient in other aspects of the healthcare industry. Besides, AI successfully implements a significant number of user sessions to find bugs that exist. Merchandise is always developed with customers in mind, and only if the merchandise resonates with customers can it be successful. It needs to be easy to use and enjoyable. Therefore, when looking for creative alternatives, designers are expected to think about usage, validate their ideas, analyze possibilities, and develop designs with medical goals in mind.

Incorporating AI can allow medical to automate the analysis of these things and be efficient in other aspects of the healthcare industry. Besides, AI successfully implements a significant number of user sessions to find bugs that exist. Merchandise is always developed with customers in mind, and only if the merchandise resonates with customers can it be successful. It needs to be easy to use and enjoyable. Therefore, when looking for creative alternatives, designers are expected to think about usage, validate their ideas, analyze possibilities, and develop designs with medical goals in mind.

Provide Relief

However, AI can provide relief from these tedious processes and will make a designer’s life much less complicated. With its vast learning and data analytics capabilities, it can help determine how people react to a particular solution, which in turn allows designers to come up with creative products. By collecting behavioral signals, teams can assess common edge cases and strategies to overcome these problems. In turn, during the design phase, artificial intelligence retains the ability to demonstrate the likelihood of success of your product design in advance.